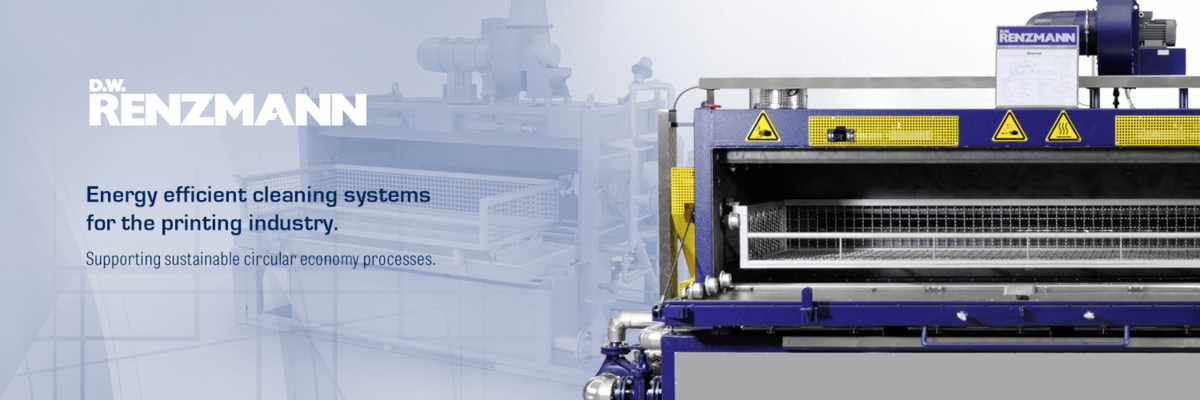

Washing machine type 365

Type 365

Cleaning of hollow cylinders

The RENZMANN washing machine model 365S has been de- signed exclusively for simultaneous cleaning of several hollow impression cylinders. Together, the short spraying distance, high spraying pressure, and the rotation of the cylinders ensure an op- timum cleaning result. The cylinder faces are additionally cleaned with brushes. The cylinders are loaded onto a hydraulic door that opens to a horizontal position in front of the machine. The cylin- ders are pushed onto the support shafts fastened to the door. As the door folds up by 90° to close the machine, the hollow cylinders are brought to a vertical position inside the washing chamber. This allows any residual liquid inside to drain from the cylinders.

The machine conforms to the safety requirements for solvent washing machines, explosion protection according to ATEX: cate- gory 1/2, explosion group IIB, temperature class T3, type examina- tion no. IBExU03ATEX1125X.

- Closed washing chamber; metal housing reinforced with a rect- angular tube frame; solvent-resistant coating

- The number, length and diameter of the cylinders depend on the machine version

- Hinged door with lateral hydraulic cylinders for opening and closing; one support shaft per hollow cylinder, fastened to the rear (bottom) of the door with a sturdy tapered roller bearing and driven by a gear motor flanged to the outside of the ma- chine; the support shafts protrude toward the loading side at the front to allow for the fitting of the hollow cylinders

- Internal solvent tank, separated from the washing chamber

- One spraying system each for washing and rinsing; compressed air controlled rinsing valve

- Filling connection with pneumatic valve

- Washing pump, 60 m liquid column; approx. 5.5 to 6 bars deliv- ery pressure, depending on the solvent; delivery volume (m³/h) and driving power (kW) depending on the machine version (num- ber and size of cylinders)

- Large-surface strainer baskets (removable from the outside) protect pumps, pipes and the spraying system from foreign mat- ter

- Brushes for removal of heavy residues on the cylinder faces; the brushes are engaged and pressed against the cylinders pneumatically during cylinder rotation and disengaged before rinsing; driven by external pneumatic cylinders

- Automatic washing program with the following program steps: washing – draining – rinsing – ventilating; simultaneous cylin- der rotation, engagement and disengagement of the brushes for cleaning of the cylinder faces

- Explosion-proof control elements mounted directly at the ma- chine: washing program ON/OFF, EMERGENCY STOP, washing time selection (SHORT/LONG), OPEN/CLOSE door, signal lamps

- Control cabinet with programmable logic controller (PLC) for in- stallation outside the hazard area; display for text in the control cabinet door; input and/or display of the duration of the individ- ual program steps

- Separate control box for the pneumatic system (maintenance of pneumatic elements can be performed without opening the control cabinet; electric components are not exposed to damp compressed air)

Request More Information

Downloads

D.W. RENZMANN Apparatebau GmbH

Industriestraße 1

55569 Monzingen

GERMANY

Phone: +49 6751 878 0

Fax: +49 6751 878 111

![[Translate to Englisch:] Home](/fileadmin/_processed_/a/7/csm_dw-renzmann_logo-2018_37677b2184.png)