For the highest cleaning requirements

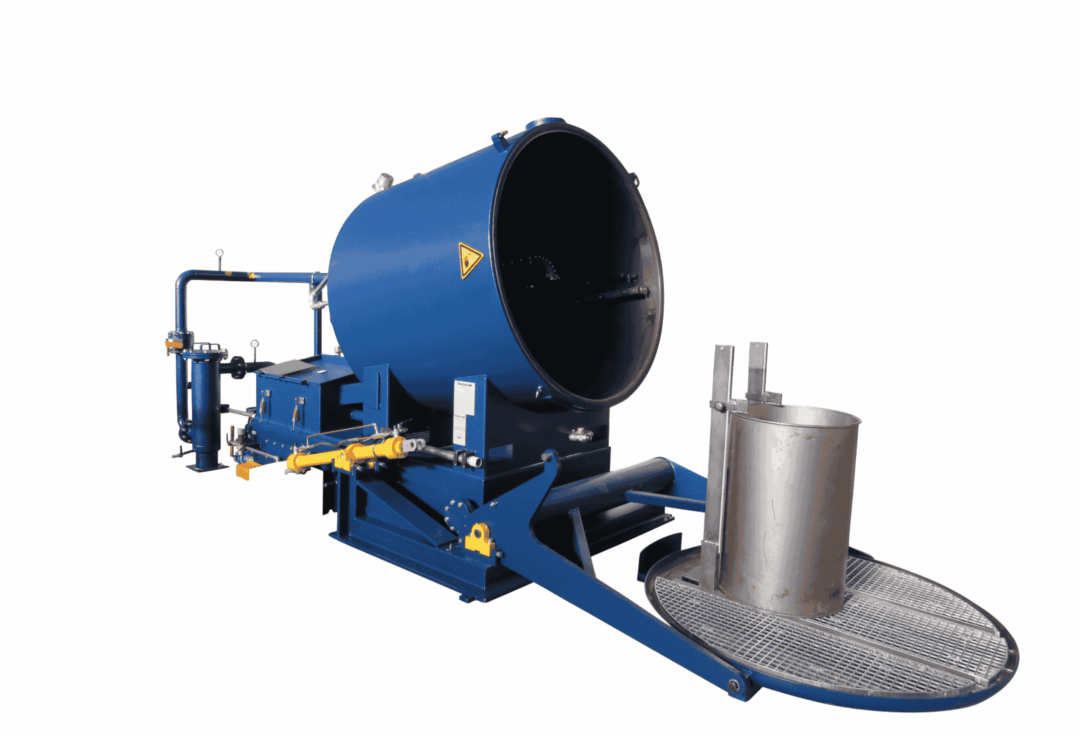

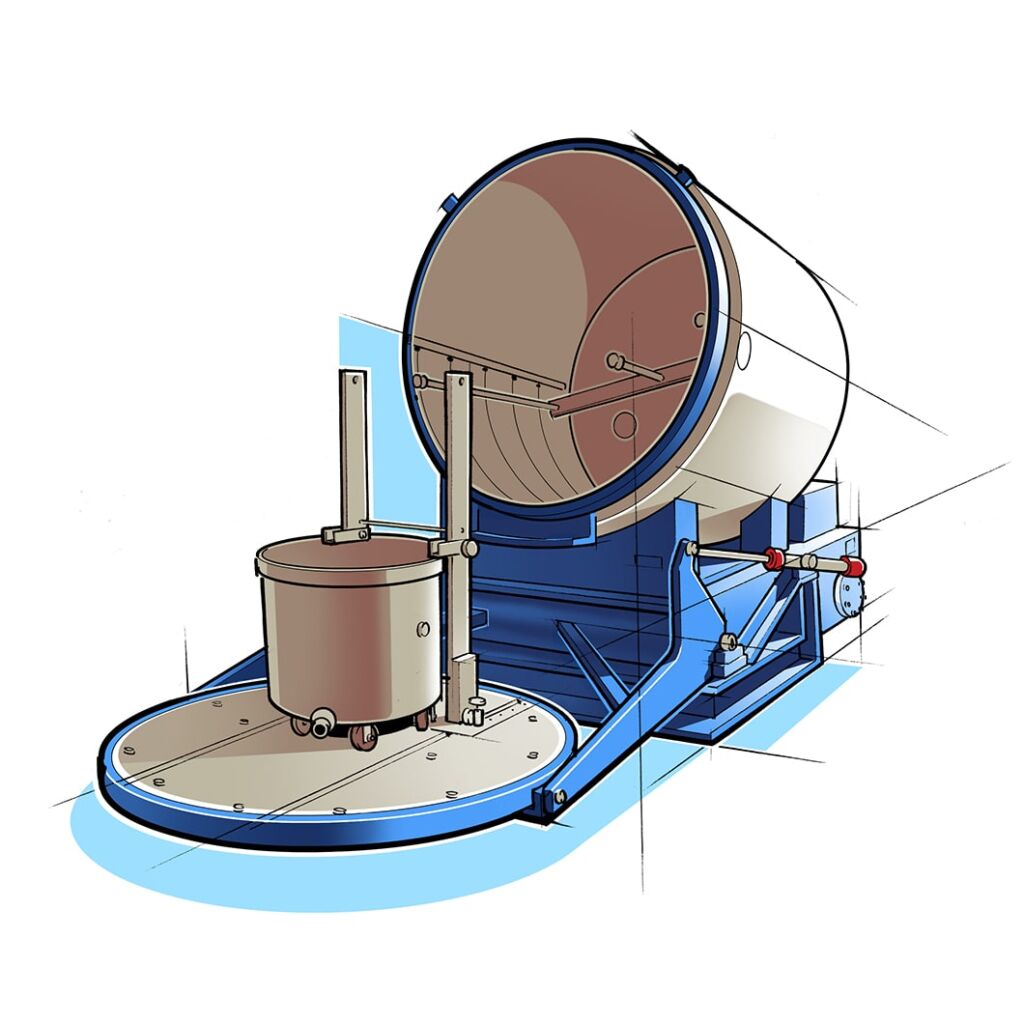

Washing machine SKM

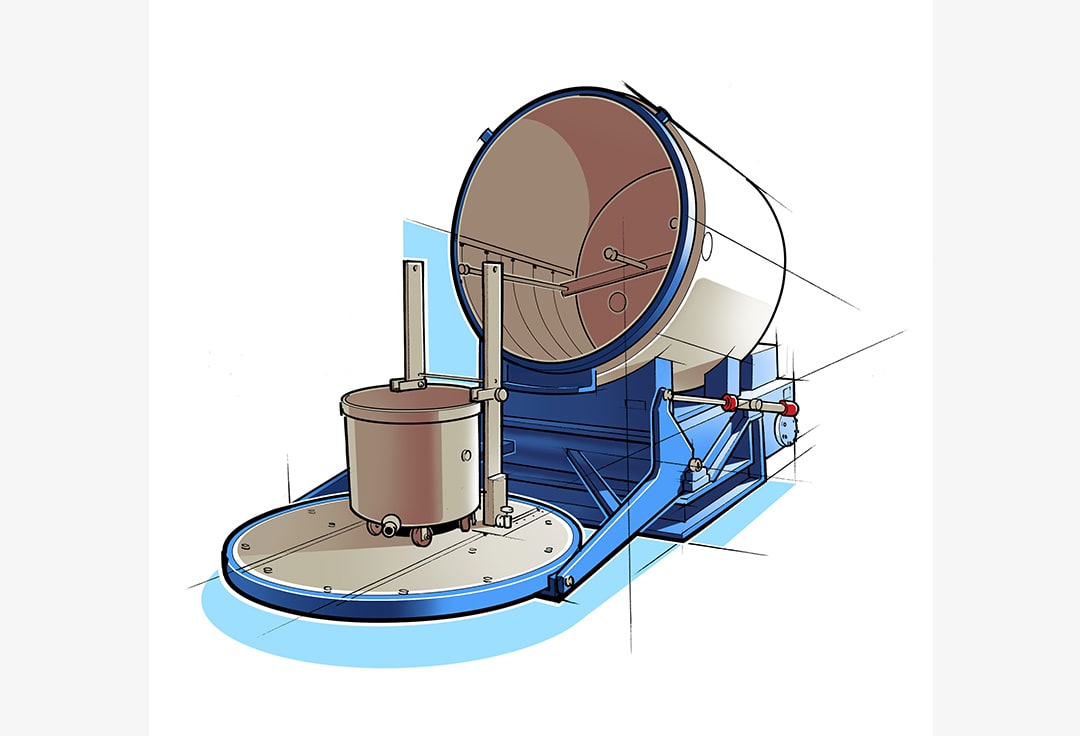

Preparation container

Mixing vessel

Mixing container

Transport containers

The SKM is a powerful, explosion-proof cleaning solution for cleaning the inside and outside of open-top containers. With rotating spray pipes and a separate rinsing system, it achieves excellent cleaning results even with large container diameters. Its sophisticated design ensures low-emission processes and particularly convenient handling - ideal for industrial applications with the highest safety requirements.

Washing machine SKM

Key features

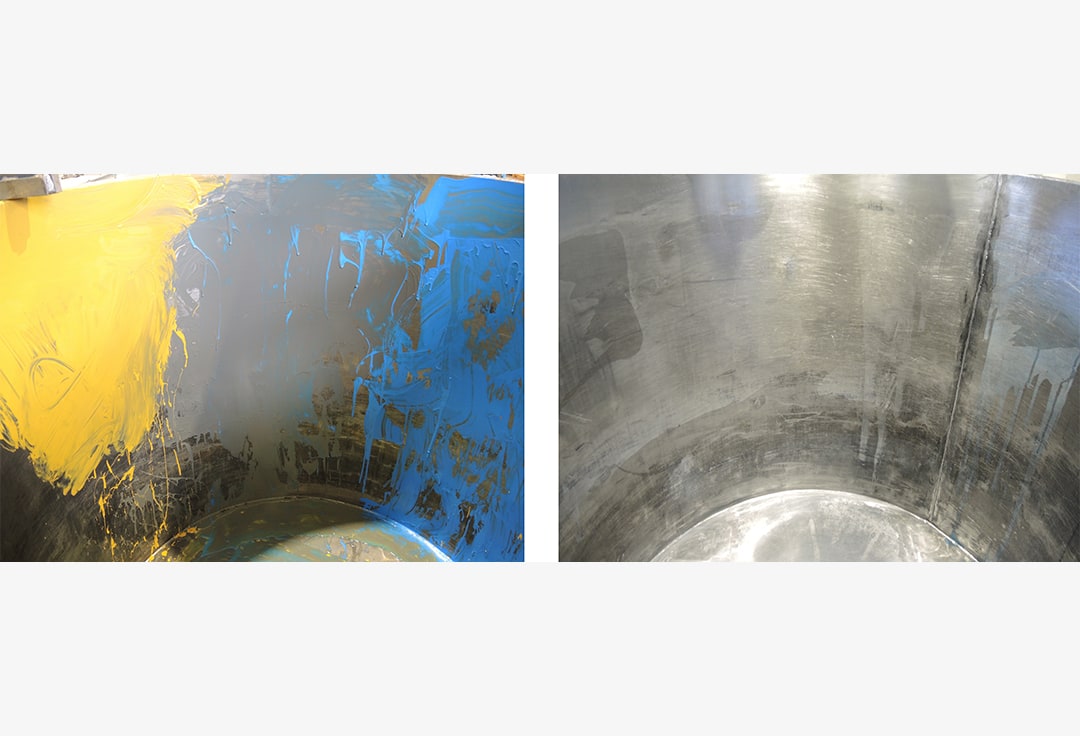

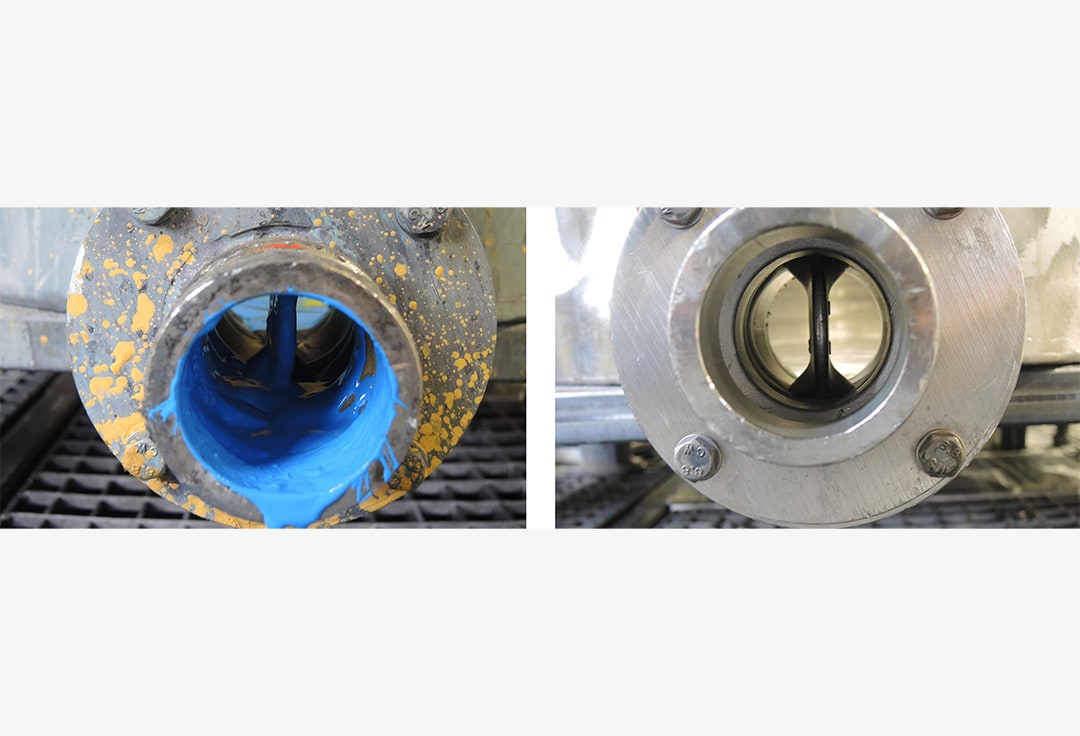

Cleaning result

- Interior cleaning with rotating spray lance - ideal for large containers

- External cleaning via rotating spray pipes around the container

- Separate rinsing system with fresh solvent for residue-free cleaning

- High-performance centrifugal pump for the circulation system, separate centrifugal pump for rinsing

- External filter with removable basket and strainer to protect the spray system, pump and washing solvent

comfort

- Hydraulically operated, tightly closing wash chamber door serves as a loading platform when open

- Cylindrical washing chamber tilted backwards - optimized solvent drainage, no residues

- Automatic washing program: Washing – Rinsing – Internal suction; Program steps can be set individually

- Closed washing solvent reservoir under the washing chamber with level switch

- Pneumatic diaphragm pump for draining the system

- Door position monitoring: spraying process only when the chamber is fully closed

- Explosion-proof hydraulic unit

Security

- Explosion-proof and ATEX-certified design for safe use in potentially explosive atmospheres

- Internal extraction with powerful extraction fan reduces emissions

- Closed solvent system - no open evaporation when opening the chamber

- Robust design with high-quality components (pumps, fans) for a long service life

Do you need more?

Get the most out of your machine with the right accessories. Optimize your processes and improve process reliability, working comfort and cleaning quality - individually tailored to your requirements and industry standards.

Cleaning result

- Separate outlet cleaning for hard-to-reach areas inside the container

- Hot air drying - effective for low volatile solvent residues

comfort

- Ramp to loading platform (approx. 150 mm) or ground-level access via pit installation

- Solvent cooling - temperature and emission-controlled operation, individually adjustable

Process reliability

- External extraction to supplement or replace the workplace extraction system

- Solvent concentration measurement and control system for connection to exhaust air purification systems

Further information

All details at a glance: Download the product flyer or send us your request for an individual consultation.

TYPE SKM-W (like water) for cleaning with aqueous alkaline media like type SKM, but with the following differences:

- Suitable for aqueous/alkaline media

- Heating of the cleaning medium, thermal insulation of the washing chamber and cleaning medium tank

- Rinsing with water

- Storage of cleaning medium and rinsing water in separate free-standing tanks (optional for floor tanks)

- Explosion protection adapted to the cleaning medium with the impurities it contains and to the requirements of the installation area

Our ATEX protection concept

Others promise, Renzmann delivers safety

Conclusion

The SKM impresses with its powerful cleaning performance, well thought-out design and maximum operational safety - while at the same time being extremely user-friendly. Ideal for demanding industrial applications that require thorough internal and external cleaning. Contact us for advice and a customized offer!

FAQ Sales

Sales

How do I get a quote?

It's easy to get a quote: Contact us by email at sales@dw-renzmann.de or call us on +49 (0) 6751 878-0. Together, we will analyze your needs - e.g. which parts you want to clean or which solvent you want to treat - and prepare a tailor-made offer for you.

Who is my contact for advice and technical questions?

Our sales staff will support you with their in-depth specialist knowledge. In addition, the sales staff work closely with our technical center so that application tests can also be carried out if required.

Who is responsible for my country or region?

We have a worldwide sales network. You can find the contact person responsible for your region here. Alternatively, our sales team will be happy to help you directly and put you in touch. For customers in Germany (and selected other countries), sales are handled directly by our company headquarters in Monzingen.

How do I find out which cleaning or distillation system suits my needs?

Our consultation begins with an individual inquiry about your requirements and wishes. You tell us your requirements - for example, which parts, containers or solvents you use - and we recommend the right machine for you. For more complex requirements or uncertainties, we offer you washing or distillation tests in our technical center. This allows you to experience under real conditions which system is best suited for you. You can request an appointment for a washing or distillation test directly here.

What information does Renzmann need for an initial assessment?

We need some basic information to provide targeted advice: What is to be purified or distilled? In what quantities? How heavy is the contamination? Are there special geometries or requirements for the cleaning or recovery result? Describe your task to us by e-mail. We will then be happy to send you the appropriate questionnaire. Based on this query, we can create a customized concept for your application.

What special solutions are possible?

Our machines are based on proven technology, but can be adapted to customer-specific requirements at additional cost. These include, for example, special adapter systems, control concepts suitable for integration, adaptations to structural conditions or special process-related functions. Simply contact us - together we will check what is technically feasible and economically viable.

Does Renzmann also offer international deliveries?

Yes, we deliver worldwide and have decades of experience in the production of machines for the international market. Our machines meet country-specific requirements, both in terms of technical standards and regulations as well as documentation. Our local sales partners also support you with communication and project management.

How quickly can I expect an offer?

Generally, you will receive your quotation within a few working days. More complex projects that require technical consultation or trials in the technical center may take a little longer. We will keep you informed of the status in a transparent manner. Request a quote.

How does Renzmann position itself when it comes to safety?

We supply ATEX-compliant machines for operation with flammable solvents. This is based on Directive 2014/34/EU (current version) and the associated guidelines of the EU Commission. With our distillation units, however, we go one step further than other suppliers. Unlike other manufacturers, we define Zone 0 inside our distillation units. This means that, in addition to all electrical devices, all moving mechanical parts inside the distillation bubble are also type-tested and approved for permanent operation in Ex Zone 0. You can find out more under "Our ATEX protection concept".

How does Renzmann position itself when it comes to sustainability and environmental protection?

Sustainability is not an add-on for us, but part of our technology philosophy: our distillation units allow for the recovery and reuse of solvents, thereby reducing disposal costs and resource consumption. Our washing machines are designed so that cleaning media can be used efficiently and processes can be designed to conserve resources. The durability of our machines also contributes to the environmental footprint.

How can I get an impression of the Renzmann machines?

Some of our machines for washing and distillation tests are available in our technical center in Monzingen. You can experience them live during a test with your own materials. Alternatively, we will be happy to send you technical documentation or reference reports - we can also organize a digital viewing appointment on request. You can find out more about our technical center here.

WE ARE HERE FOR YOU

If you need technical details about our machines or individual advice -

We will be happy to help you!