Safe and efficient manual washingLarge parts cleaning under explosion protection

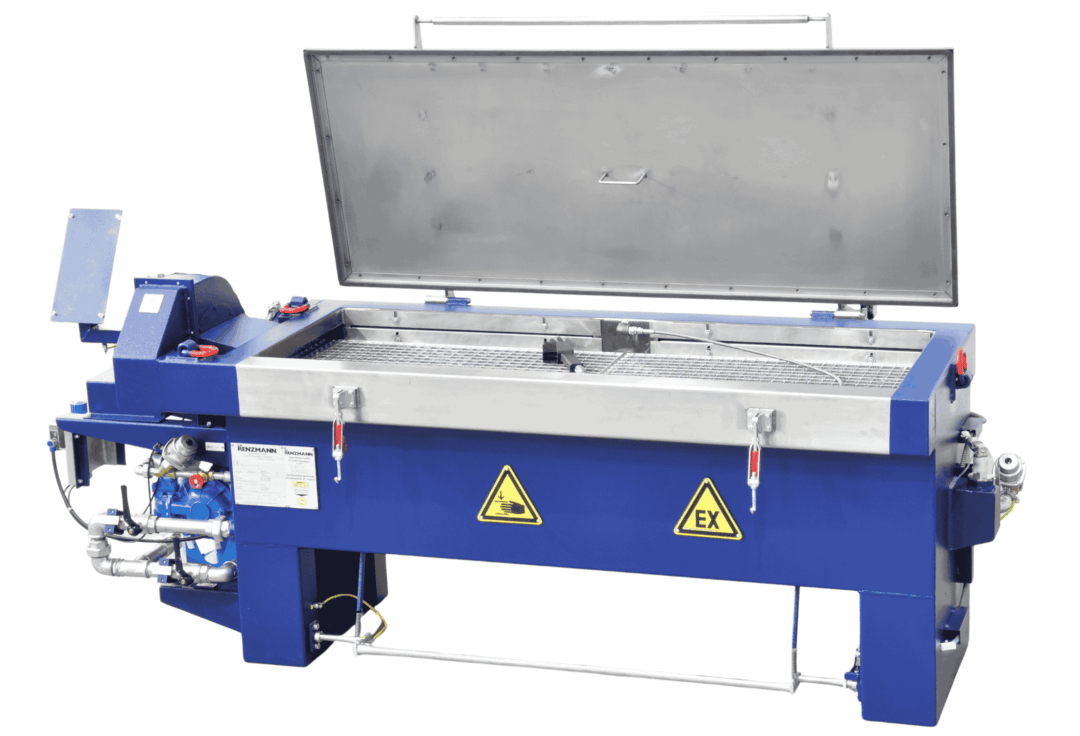

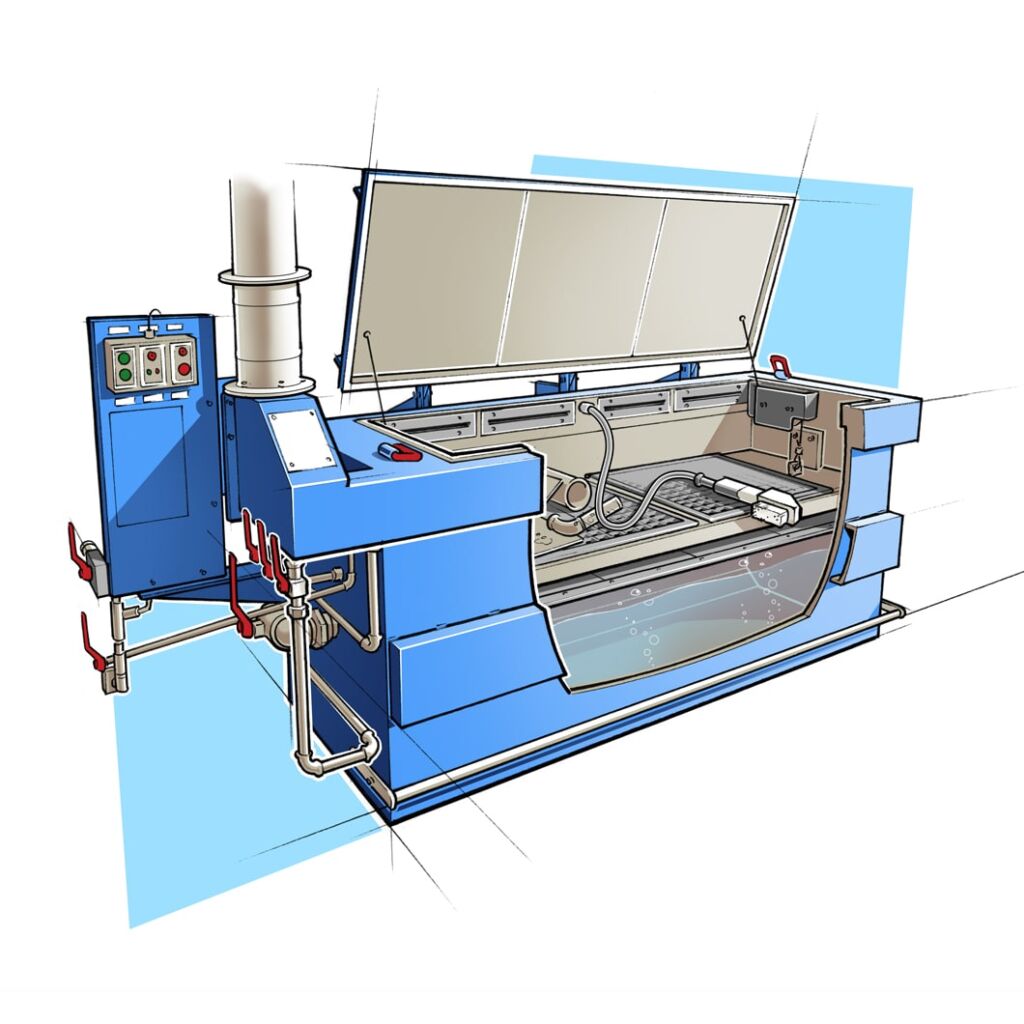

Hand washing station HP

Squeegee

Agitators

Tubs

Fittings

Slider

Trowels

Hobbocks

Rollers

Hoses

Pumps

Printing unit parts

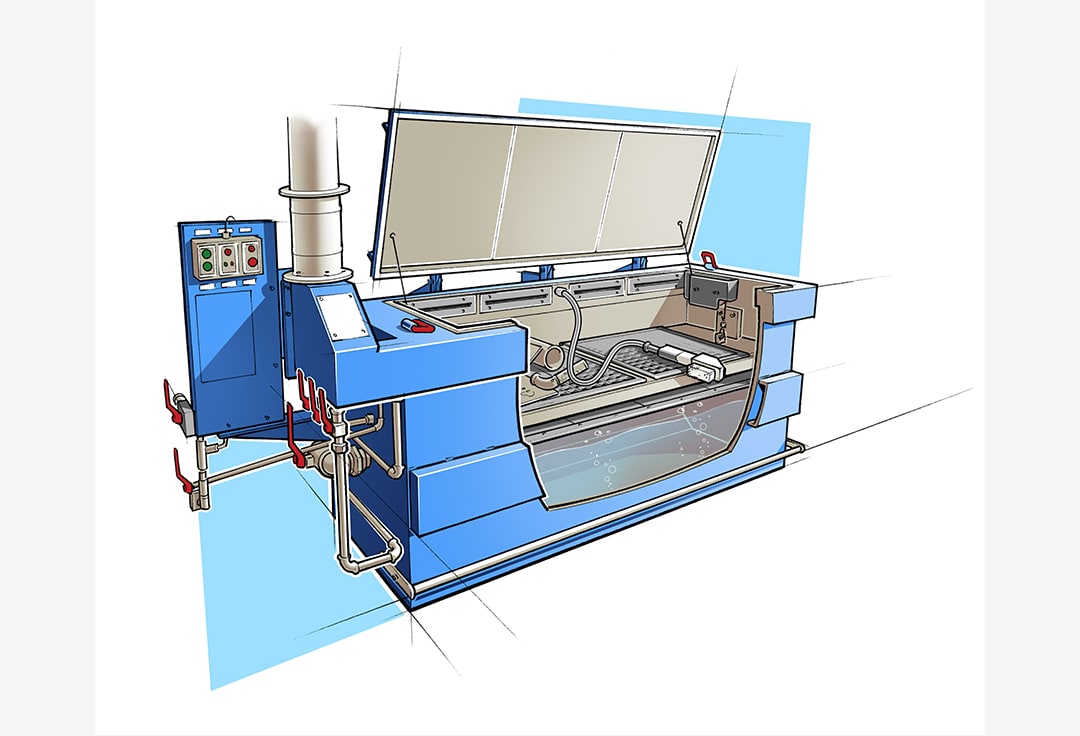

The HP hand washing station is an explosion-proof, ATEX-compliant device for manual washing with all common solvents. Equipped with a safety hand washing brush, hinged lid and integrated washing solvent reservoir, the system is ideal for industrial applications where safety, ergonomics and efficiency are paramount. Thanks to the pneumatic diaphragm pump and dead man's control, the HP impresses with its sophisticated technology in the smallest of spaces.

Hand washing station HP

Key features

Cleaning result

- Manual washing possible with all common solvents

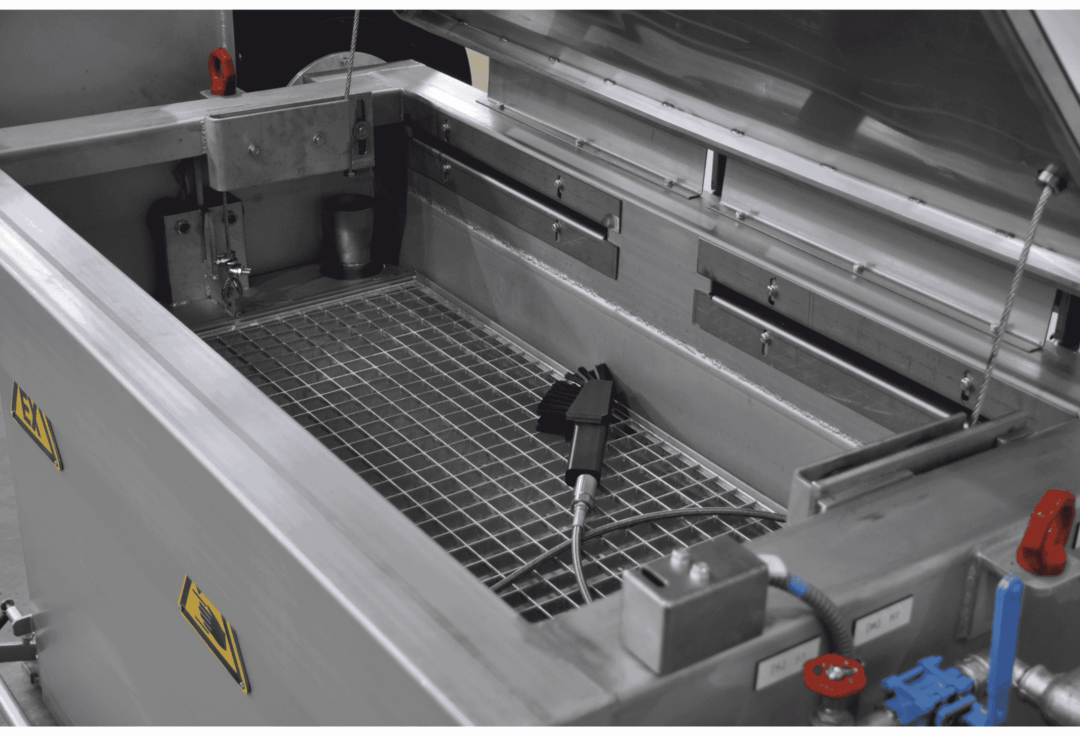

- Grid for stable and safe storage of wash items

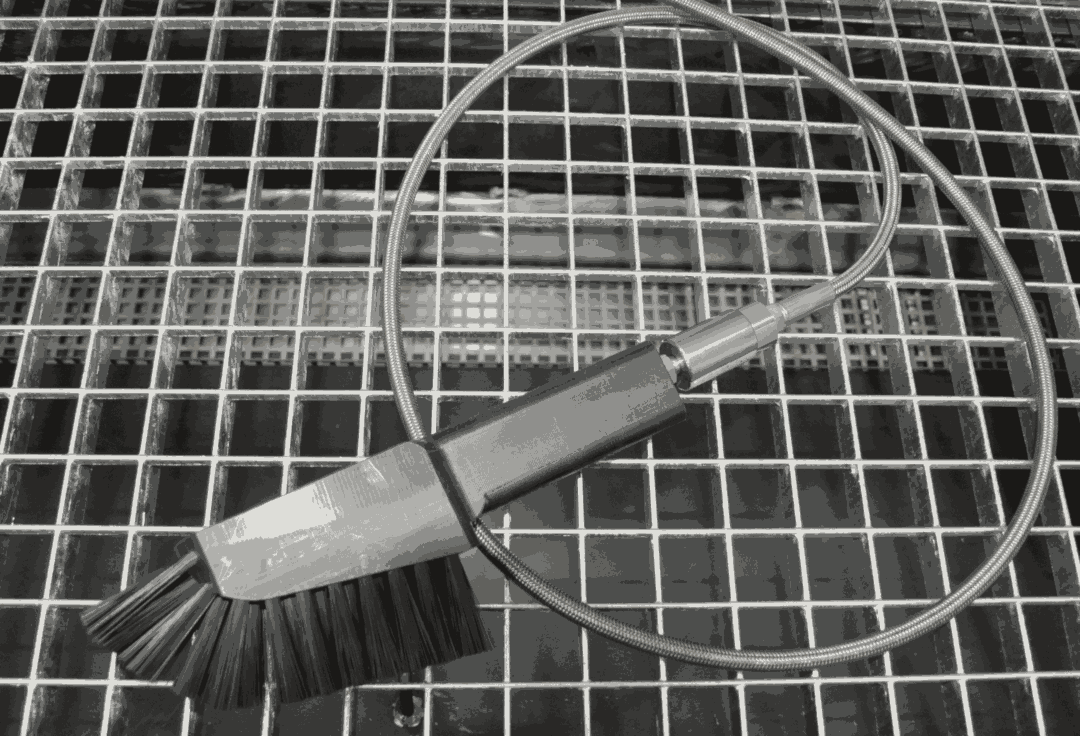

- Safety hand washing brush with adjustable flow rate

- Screen filter between washing chamber and solvent supply

Convenient handling

- Hinged lid with simple operation

- Separately integrated washing solvent reservoir in the housing

- Start of solvent supply via baseboard (dead man's switch)

- Pneumatic diaphragm pump for filling, emptying and brush supply

- Optical fill level marking for easy checking

Security

- Ex-protected and ATEX-compliant design

- Internal extraction system with powerful fan and vacuum flaps

- Safety hand washing brush with pressure-reducing fitting

- Solvent supply only with active foot operation - dead man's principle

- Pneumatic operation for increased operational safety in sensitive areas

- Robust design with high-quality components (pumps, fans) for a long service life

Do you need more?

Get the most out of your machine with the right accessories. Optimize your processes and improve process reliability, working comfort and cleaning quality - individually tailored to your requirements and industry standards.

Cleaning result

- Cleaning device for very small parts

- Immersion bath equipment for soaking stubborn soiling

Convenient handling

- Pneumatically operated hinged lid

- Automatic filling and emptying - via existing systems or mobile containers

Process reliability

- Alternative version with stainless steel housing for special environments

Further information

All details at a glance: Download the product flyer or send us your request for an individual consultation.

Our ATEX protection concept

Others promise, Renzmann delivers safety

Your safe solution for manual washing

The HP hand washing station provides you with a safe, ergonomic and efficient solution for manual solvent washing in ATEX zones. Whether as an individual workstation or as part of a larger cleaning concept - this device impresses with its efficiency, safety and ease of use. Ideal for workshops, paint stores or industrial cleaning processes in print shops. Contact us - we will be happy to advise you!

FAQ Sales

Sales

How do I get a quote?

It's easy to get a quote: Contact us by email at vertrieb@dw-renzmann.de or call us on +49 (0) 6751 878-0. Together, we will analyze your needs - e.g. which parts you want to clean or which solvent you want to treat - and prepare a tailor-made offer for you.

Who is my contact for advice and technical questions?

Our sales staff will support you with their in-depth specialist knowledge. In addition, the sales staff work closely with our technical center so that application tests can also be carried out if required.

Who is responsible for my country or region?

We have a worldwide sales network. You can find the contact person responsible for your region here. Alternatively, our sales team will be happy to help you directly and put you in touch. For customers in Germany (and selected other countries), sales are handled directly by our company headquarters in Monzingen.

How do I find out which cleaning or distillation system suits my needs?

Our consultation begins with an individual inquiry about your requirements and wishes. You tell us your requirements - for example, which parts, containers or solvents you use - and we recommend the right machine for you. For more complex requirements or uncertainties, we offer you washing or distillation tests in our technical center. This allows you to experience under real conditions which system is best suited for you. You can request an appointment for a washing or distillation test directly here.

What information does Renzmann need for an initial assessment?

We need some basic information to provide targeted advice: What is to be purified or distilled? In what quantities? How heavy is the contamination? Are there special geometries or requirements for the cleaning or recovery result? Describe your task to us by e-mail. We will then be happy to send you the appropriate questionnaire. Based on this query, we can create a customized concept for your application.

What special solutions are possible?

Our machines are based on proven technology, but can be adapted to customer-specific requirements at additional cost. These include, for example, special adapter systems, control concepts suitable for integration, adaptations to structural conditions or special process-related functions. Simply contact us - together we will check what is technically feasible and economically viable.

Does Renzmann also offer international deliveries?

Yes, we deliver worldwide and have decades of experience in the production of machines for the international market. Our machines meet country-specific requirements, both in terms of technical standards and regulations as well as documentation. Our local sales partners also support you with communication and project management.

How quickly can I expect an offer?

Generally, you will receive your quotation within a few working days. More complex projects that require technical consultation or trials in the technical center may take a little longer. We will keep you informed of the status in a transparent manner. Request a quote.

How does Renzmann position itself when it comes to safety?

We supply ATEX-compliant machines for operation with flammable solvents. This is based on Directive 2014/34/EU (current version) and the associated guidelines of the EU Commission. With our distillation units, however, we go one step further than other suppliers. Unlike other manufacturers, we define Zone 0 inside our distillation units. This means that, in addition to all electrical devices, all moving mechanical parts inside the distillation bubble are also type-tested and approved for permanent operation in Ex Zone 0. You can find out more under "Our ATEX protection concept".

How does Renzmann position itself when it comes to sustainability and environmental protection?

Sustainability is not an add-on for us, but part of our technology philosophy: our distillation units allow for the recovery and reuse of solvents, thereby reducing disposal costs and resource consumption. Our washing machines are designed so that cleaning media can be used efficiently and processes can be designed to conserve resources. The durability of our machines also contributes to the environmental footprint.

How can I get an impression of the Renzmann machines?

Some of our machines for washing and distillation tests are available in our technical center in Monzingen. You can experience them live during a test with your own materials. Alternatively, we will be happy to send you technical documentation or reference reports - we can also organize a digital viewing appointment on request. You can find out more about our technical center here.

WE ARE HERE FOR YOU

If you need technical details about our machines or individual advice -

We will be happy to help you!